Test procedures must keep pace with the HUDs of the future: High-precision HUD test bench measures head-up displays fully automatically

Nowadays, hardly any vehicle manufacturer does without an integrated head-up display (HUD) in new models. And for good reason: the new systems have been proven to increase road safety and are regarded as pioneering. However, HUDs also come with a number of challenges that can have a disruptive effect on driving performance. For example, the displays can be difficult to read in strong sunlight or poor illumination, while incorrect settings can even dazzle or significantly distract the driver. Comprehensive test series are required to rule out such problems in advance. OEMs must either rely on the results from suppliers or invest heavily in their own test benches. Many existing test benches on the market rely on old measurement methods whose accuracy and measurement diversity no longer do justice to technological developments, which is why lengthy comparative measurements are required. ARRK Engineering has therefore developed a new high-precision HUD test bench in collaboration with the test bench specialist Gefasoft, into which the complete windscreen can also be clamped. This means that even pioneering new HUD technologies, which are currently being increasingly developed by OEMs, can still be measured. Regardless of the manufacturer, various optical properties can be recorded fully automatically and much more precisely than before with a high degree of repeatability, as confirmed by a measurement capability test.

When the industry gathered at the IAA Mobility in Munich in 2023, augmented reality head-up displays (AR HUD) were one of the hot topics. In contrast to just a few years ago, HUDs are no longer considered a cost-intensive "gimmick", but have become an integral part of new vehicle models as a driver assistance system or, for some manufacturers, will even be the main display system in vehicles in the future. By displaying relevant information such as speed and navigation as well as warnings and infotainment directly in the driver's field of vision, it is less necessary to take your eyes off the road. In the case of future-oriented AR HUDs, not only static information but also contact-analogue information is projected directly onto the road from the driver's perspective. In this way, ADAS (Advanced Driver Assistance Systems) such as distance and lane-keeping assistants can react dynamically to what is happening in traffic and immediately display potential sources of danger, for example. This increases driving safety in two ways compared to classic head-down displays such as an analogue or digital instrument panel with static information.

"As with all technologies, the same applies to HUDs: the more functionalities are mapped, the greater the demands on testing," says Sebastian Hensle, Group Manager Optical Systems at ARRK Engineering. "Especially in the context of new, larger HUDs or display content that is projected in the so-called black area of the windscreen, for example, it is necessary to measure the entire windscreen, which our previous test bench was simply unable to do." In turn, windscreen test benches already available on the market were not able to demonstrate the high measurement accuracy required by OEMs for complex HUD systems. A test bench that could meet the strict specifications for full-surface measurement first had to be designed. In search of a development partner for this mammoth project, ARRK Engineering turned to automation specialist Gefasoft in 2020.

Flexibly customisable and expandable for new HUD generations

"We chose Gefasoft as our project partner for two main reasons," explains Hensle. "Firstly, because of their many years of expertise in the windscreen and HUD sector and, secondly, because we were able to obtain hardware and software from a single source." This complete package ensured that all software-hardware interfaces functioned perfectly and that the test bench fulfilled the specifications defined by ARRK Engineering in terms of both hardware and software. Conventional disc test benches are not up to this challenge, as they usually have to meet less stringent requirements. "We had to modify our software accordingly in order to realise the required test scope and measurement sequences," confirms Jonathan Guthmann, Project Manager Vision/HUD at Gefasoft. "We also equipped the system with comprehensive access options and interfaces for our own extensions so that our colleagues at ARRK Engineering can keep it state of the art in the future and adapt it to the challenges of new HUD generations."

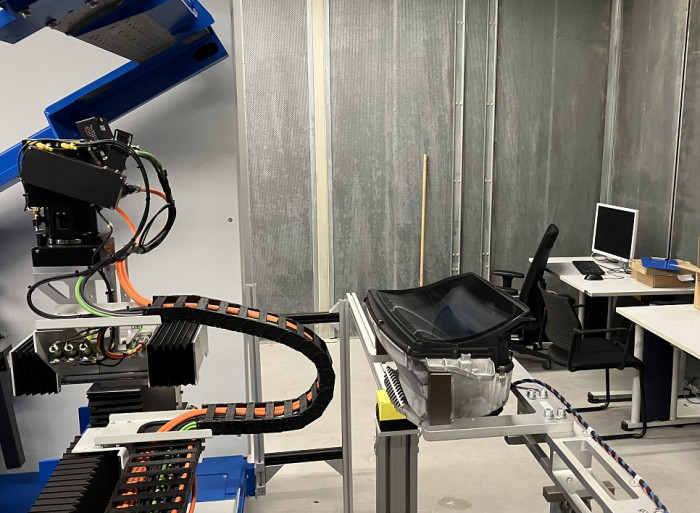

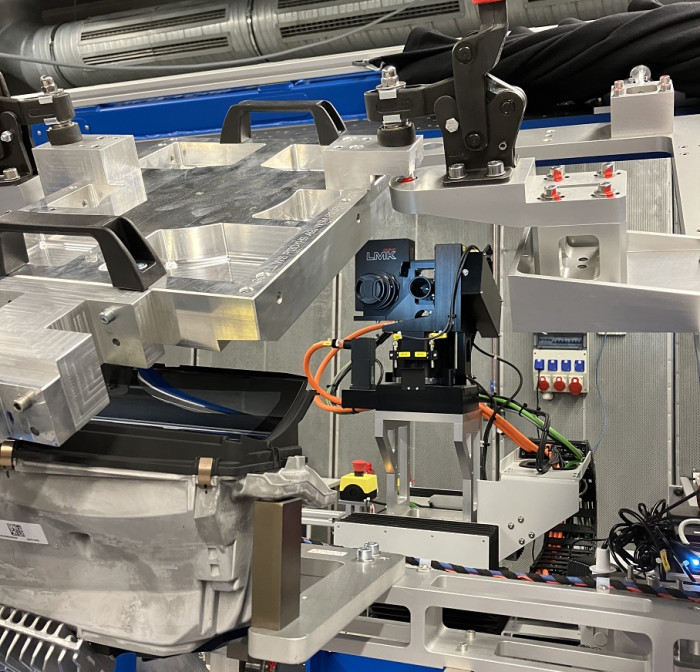

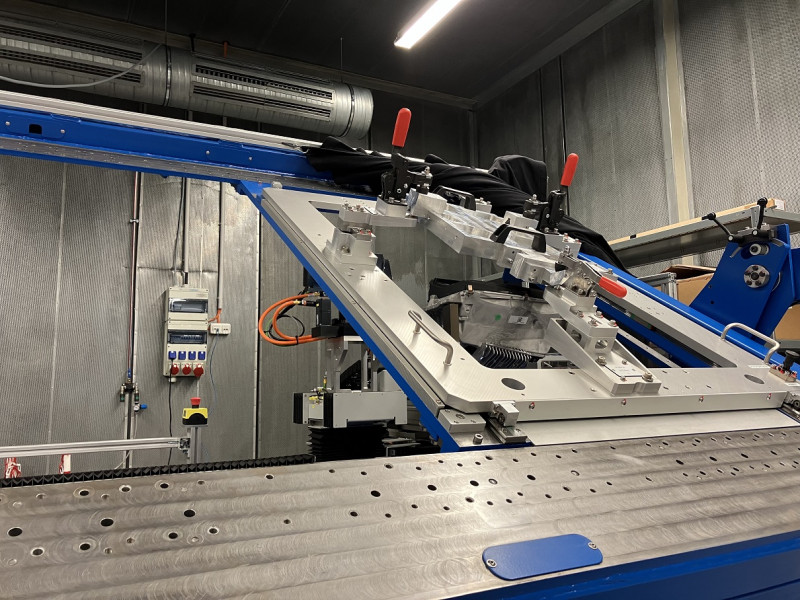

The flexible design of the test stand was the second major requirement on the part of ARRK Engineering. In order to improve the workflow when inserting a new HUD projector, Gefasoft designed an automated conveyor line for moving the projector from the change position to the test position. In addition, the disc master, which imitates the topology of the windscreen for the test purpose, can also be moved to a safe changing position, where it can be replaced in a few simple steps. "The windscreen itself is also becoming increasingly important as part of the overall HUD system," explains Hensle. "That's why we designed the new test bench on the basis of a disc test bench from the outset." As an alternative to the so-called windscreen master (windscreen cut-out usually made of stainless steel), it is also possible to place the entire windscreen for testing - regardless of manufacturer or vehicle type. "This will become very relevant for future 3D or AR HUDs, as ever larger areas of the windscreen will be used as a contact-analogue projection surface," adds project manager Alexander Düring, GEFASOFT.

Investment in the future: test bench measures 5 times more precisely than required

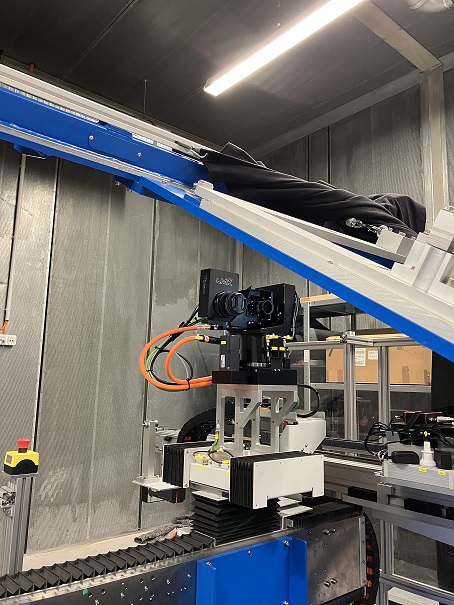

An LMK 6 colour camera from TechnoTeam was installed for the two-dimensional photometric measurements. This not only has a high-resolution sensor, but also utilises a lens with a large field of view (FOV) for this purpose. It complements the standard setup for distortion measurement. "We originally wanted to use a measuring robot to guide the camera," reports Hensle. "However, the articulated arms could not fulfil our strict specifications for the measurement tolerances." The camera is therefore now guided by a linear system, which enables a positioning inaccuracy of less than a tenth in all camera positions with a maximum travel distance. In addition, there is the factor of mechanical stability, which was given high priority in the test stand weighing around 3.5 tonnes. As a result, such high measurement and repeatability accuracy can be achieved in the series testing of HUD projectors that the measurement capability limits specified by the OEMs are undercut by a factor of five, as has been proven in relevant test series.

Thanks to the optimised coordination of hardware and software by Gefasoft, the high-precision measurement, including the documentation and traceability of the results, is fully automated and does not need to be monitored manually. This means that it is no longer a problem to simply run longer tasks such as luminance measurements, which can easily take three to four hours, overnight. "In Gefasoft, we have gained an experienced project partner who was able to reliably realise our ideas of a highly automated yet flexibly expandable HUD test bench. We are now prepared for new generations of HUDs - whether AR HUDs, which were presented by OEMs at the IAA, or future technologies in which the testing of the windscreen as part of the complex overall system will become increasingly relevant," concludes Hensle.

Further information at https://www.gefasoft.com/ und https://engineering.arrk.com/