CAE & Simulation

With our extensive expertise in the fields of CAE & Simulation, we can get your product concept ready for series production quickly and cost-effectively. Lists of ambitious product characteristics and increasingly tight development times make it necessary to use effective CAE tools and enlist the services of experienced specialists.

Our CAE & Simulation area ensures maximum reliability in virtual development. Whether CAE-driven component development, weight optimisation or complex system analysis, you know when you come to us that you're in safe hands.

Our strengths

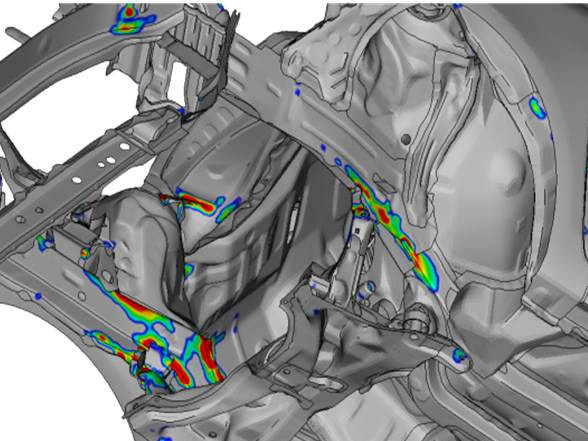

Passive safety

Development of passive safety' refers to the process of designing vehicles to minimise the consequences of accidents for passengers, victims outside of the vehicle and any other road users. A high level of passive safety is achieved by maximising energy consumption in the bodywork, synchronising restraint systems and designing the interior suitably. In this sense, passive safety is an overall function of the vehicle, and achieved through optimal device interaction.

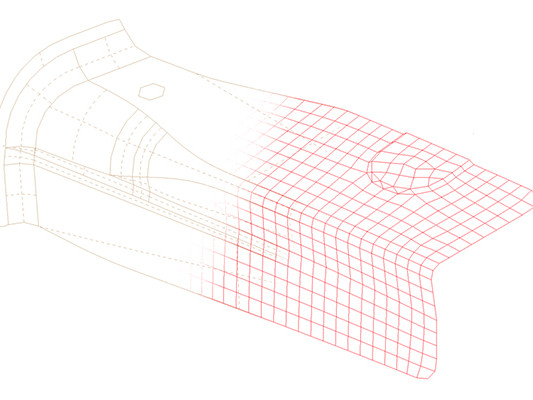

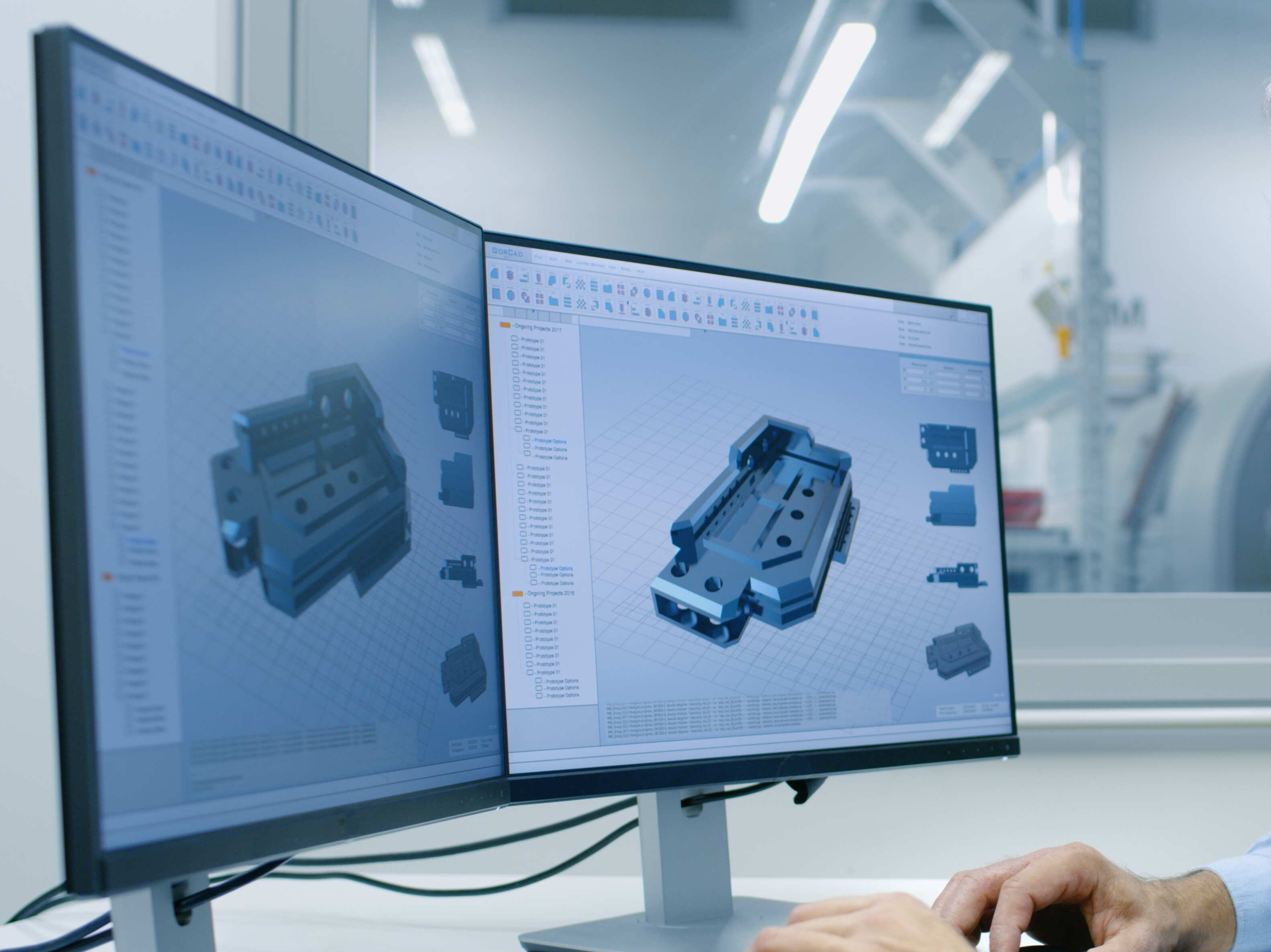

Modelling

The key to a high-quality and meaningful analysis is an underlying finite element network. Our expertise encompasses the following tasks and spheres of activity.

Task

- Models are mainly built in ANSA/Hypermesh, based on CAD data of all formats

- Construction of complete numerate includes for Nastran, Abaqus, PamCrash, LsDyna, CFD

- Creation of versions following consultations and sketches

- Assembly and equipment by means of connection technology fixtures, forces, contacts

- Crediting models for evidence of operability

- Development of derivatives via morphing (stretching/compressing components)

- Method themes for special images of connection technology...

- Evidence of operability via simulation of models

Sphere

- Complete vehicles: building structure, doors and tailgates with complete connection technology

- Interior components: seat, dashboard, center console, door paneling, roof lining

- Exterior components: shaft spider, engine, transmission, HV storage, exhaust systems

- Bus and truck

- Motorcycle: frame, plastic components, engine components, suspension

- Aerospace: fuselage sections, ventilation system, flap tracks

- Ship: hull shell

- Train: rail cars

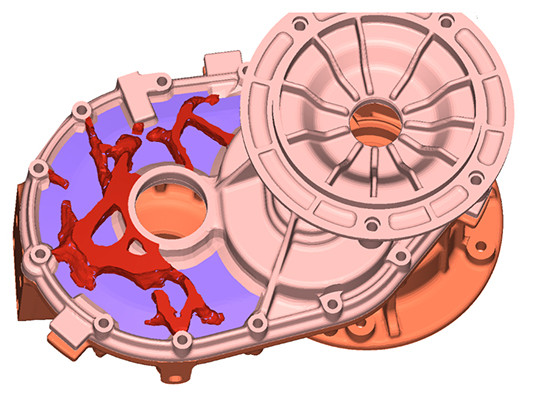

Stiffness and strength

To ensure structures are effective, any underlying requirements regarding stiffness and strength must be optimised at an early stage. We support your development process with our solid knowledge base and can apply this expertise to all standard development environments.

- Simulation of dynamic stiffness

- Modal and harmonic response analysis

- Investigation of operational vibrations

- Calculation of system sensitivities

- Component optimisation

- Oscillation system and mass damper adjustment

Vibrations and acoustics

Drive comfort and acoustics are fast becoming major distinguishing features, causing demands to increase at the same time. We manage the simulative design and coordination process for your components and assemblies:

- Calculation of linear static stiffness

- Simulation of non-linear strength requirements

- Optimisation of topology and wall thickness

- Optimisation of layered constructions in composite structures

- Joining concepts for mixed material construction

Fatigue strength and service life

The desire for weight reduction and efficient use of materials mean there are an increasing number of challenges faced when evaluating service life. We help you to optimise the fatigue strength and service life of structural components during the design process:

- Load data calculations

- Load data analysis

- Load spectrum determination

- Service life planning for undercarriage and drive components

- Bodywork and attached part coordination

- Load path optimisation

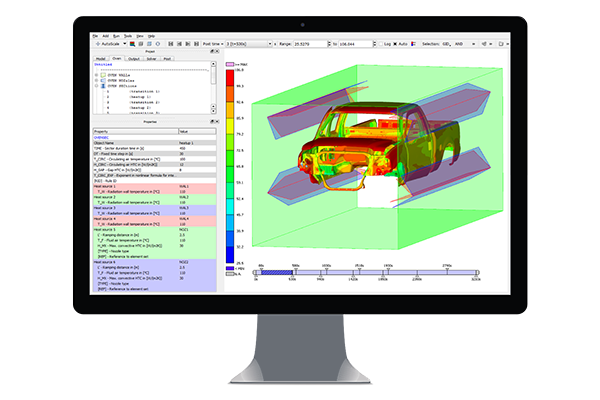

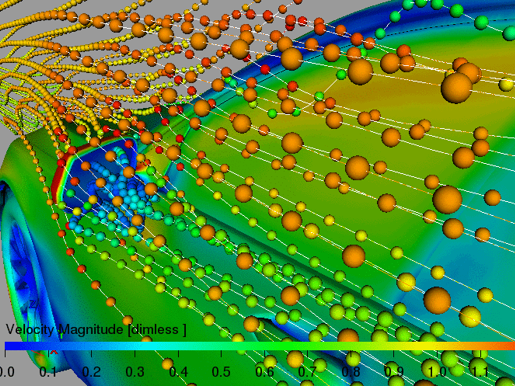

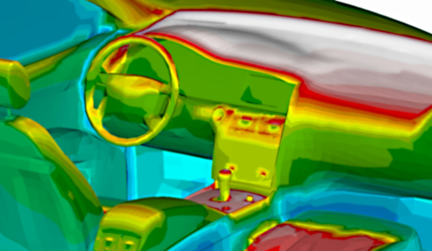

Flow calculation and thermal simulation

The 'Flow calculation and thermal simulation' department's main task is to conduct thermal analysis of systems and components. The simulation techniques used are generic and can be applied in other areas.

A series of 'focal areas' have emerged with these, however, such as the calculation of component temperature in vehicles based on engine compartment flow, air conditioning of passenger compartments and comfort ratings, calculations for cooling systems and charge cycle processes, and cooling of electrical components such as control units, batteries, LEDs and headlights.

Software and method development

We develop professional software which supports and automates CAE processes, from model design, simulation and data management to post-processing.

- Scripts and tools for automating CAE processes

- Stand-alone tools in C#/Java/Python, etc.

- Web applications with Java EE/Angular, etc.

- Simulation data management

- Professional software development with Scrum, Unitests and continuous integration

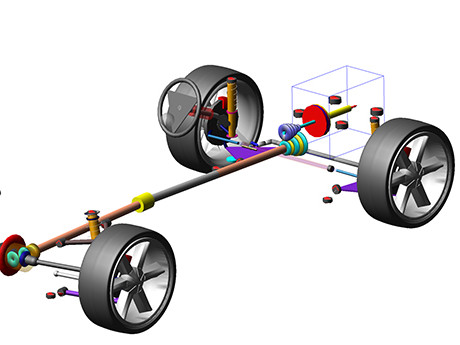

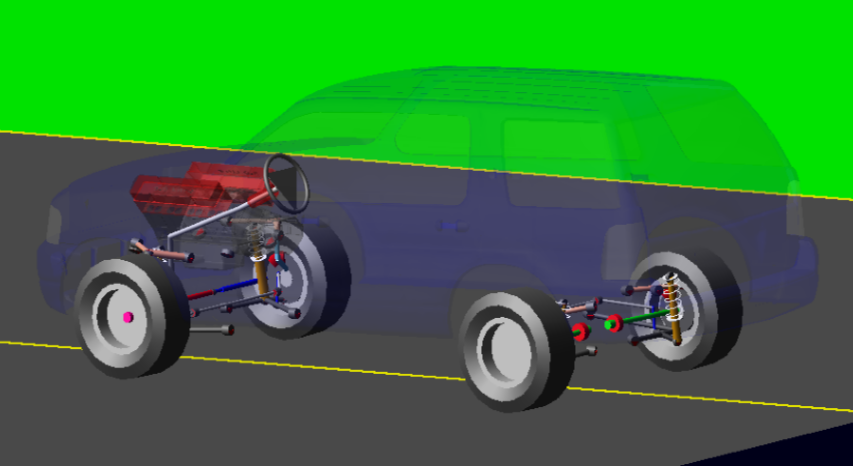

Multi-body simulations

We use multi-body simulations to help you solve any kinematic and dynamic problems and have many years of experience in the following sub-areas in particular, which includes integration of flexible chassis and variable control systems.

- Vehicle dynamics and ride comfort

- Power train simulation

- Gearbox design

- Load data calculation and analysis

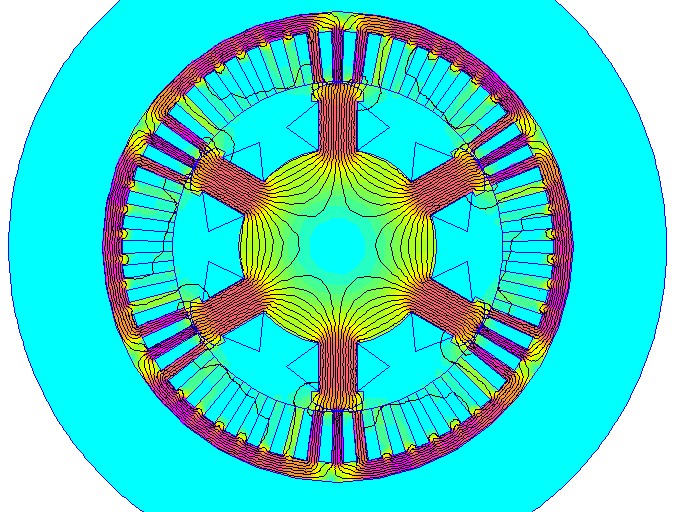

Electromagnetic simulation

By using FE calculations (2D/3D) in both the time domain and the frequency domain, we help you to solve electromagnetic issues. In all of these areas, we can fall back on our design expertise in relation to electrical machinery, electromagnetic actuators and linked systems (electrical-thermal-mechanical).

- Design of electrical and magnetic components and systems

- Electromagnetic field distribution in a wide range of materials and geometries

- Development of forces and torques due to the electromagnetic field

- Thermal behaviour of current-carrying elements (conductive heating)

- Electromagnetic induction

System simulation

In this area, we use simulation tools such as Matlab Simulink, SimulationX, Dymola and GT Suite to analyse multiphysical correlations, and can help you with the following:

- Power trains

- Regulated undercarriages

- Energy management

- Air conditioning

- Cooling systems

- Charge cycles

- Coupling and co-simulation

- Model order reduction

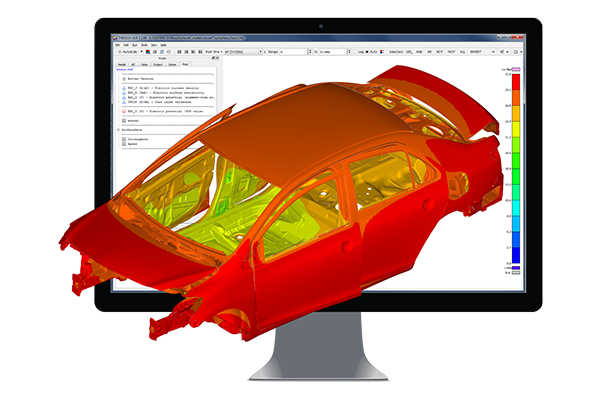

Theseus-FE software

Theseus-FE simulation software, which we developed ourselves and sell commercially, uses the finite element method as its basis and is essentially made up of the following components:

- a solver base for thermal simulations (heat conduction and radiation)

- a thermophysiological model to predict thermal comfort (e.g. inside vehicles or in buildings)

- a special module (oven) to predict bodywork temperatures in paint-drying ovens (including Abaqus user sub-routine for bodywork adhesives)

- a special module (e-coating) to simulate the thickness of the coat of paint in a cataphoretic painting container

- a powerful graphical user interface (GUI) for modelling and evaluation of results

- coupling tools, e.g. for CFD software such as Star-CCM+ and OpenFOAM

- a mapper to transmit results between different networks and result formats

THESEUS-FE is used primarily for customers in the automotive industry, but is also used by building physics and aerospace departments at universities and academic/scientific institutions. For more information about THESEUS-FE, go to http://www.theseus-fe.com