Car Body & High Voltage Battery Development

The car body is the key element of any vehicle and therefore indispensable, regardless of the car concept. From the doors to the high-voltage batteries – we have the know-how for all materials. Our expertise comes to bear on every single component. Your new electric car likewise needs a body that perfectly meets the requirements of an electric drive. In short: a car body from us.

Our development expertise in the field of car bodies

Our specialists develop car body components in a variety of materials from pilot to series development. In doing so, we focus on:

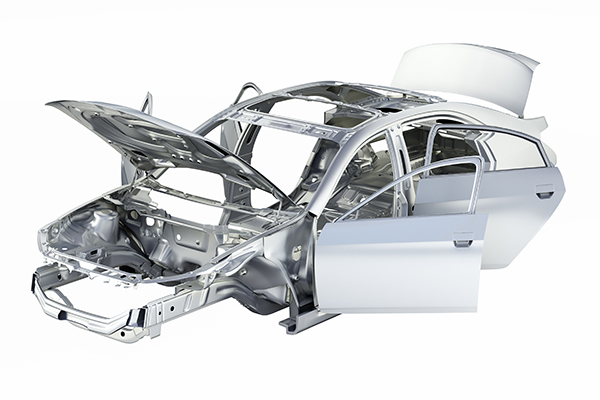

Body in white

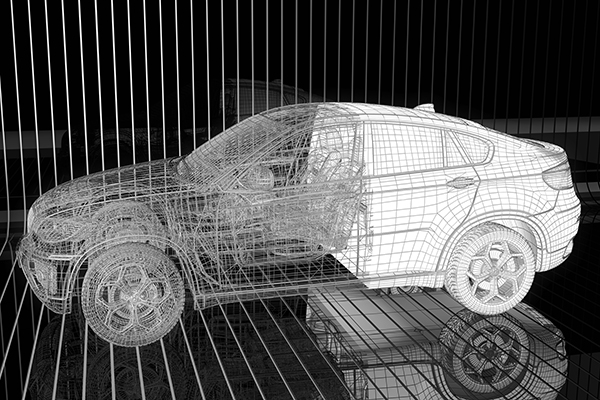

Based on customer specifications and observing production-related issues, we initially develop the car body structure into a coherent concept in the form of a 3D geometry consisting of the individual components.

In close cooperation with our internal departments, such as CAE & Simulation, and the customer’s relevant departments, the functions of the car body (crash behavior, various load cases, etc.) and the manufacturing feasibility of both its individual components and assemblies are optimized up to production maturity.

- Concept to series development

- Joining technology

- Production feasibility

Doors and hatches

Due to the stringent demands on the door and hatch modules, we work intensively with Structural Design and Structural Calculation. Our aim is to develop a complete integrated system, taking into account all safety requirements. Expert handling of the wide variety of materials, kinematic requirements, system supplier integration and interface management to the adjacent business areas allow us to offer our customers an ideal functional development.

- Door, hatch and lid assembly

- Assembly modules

- Mechanical door and hatch components

- Kinematics

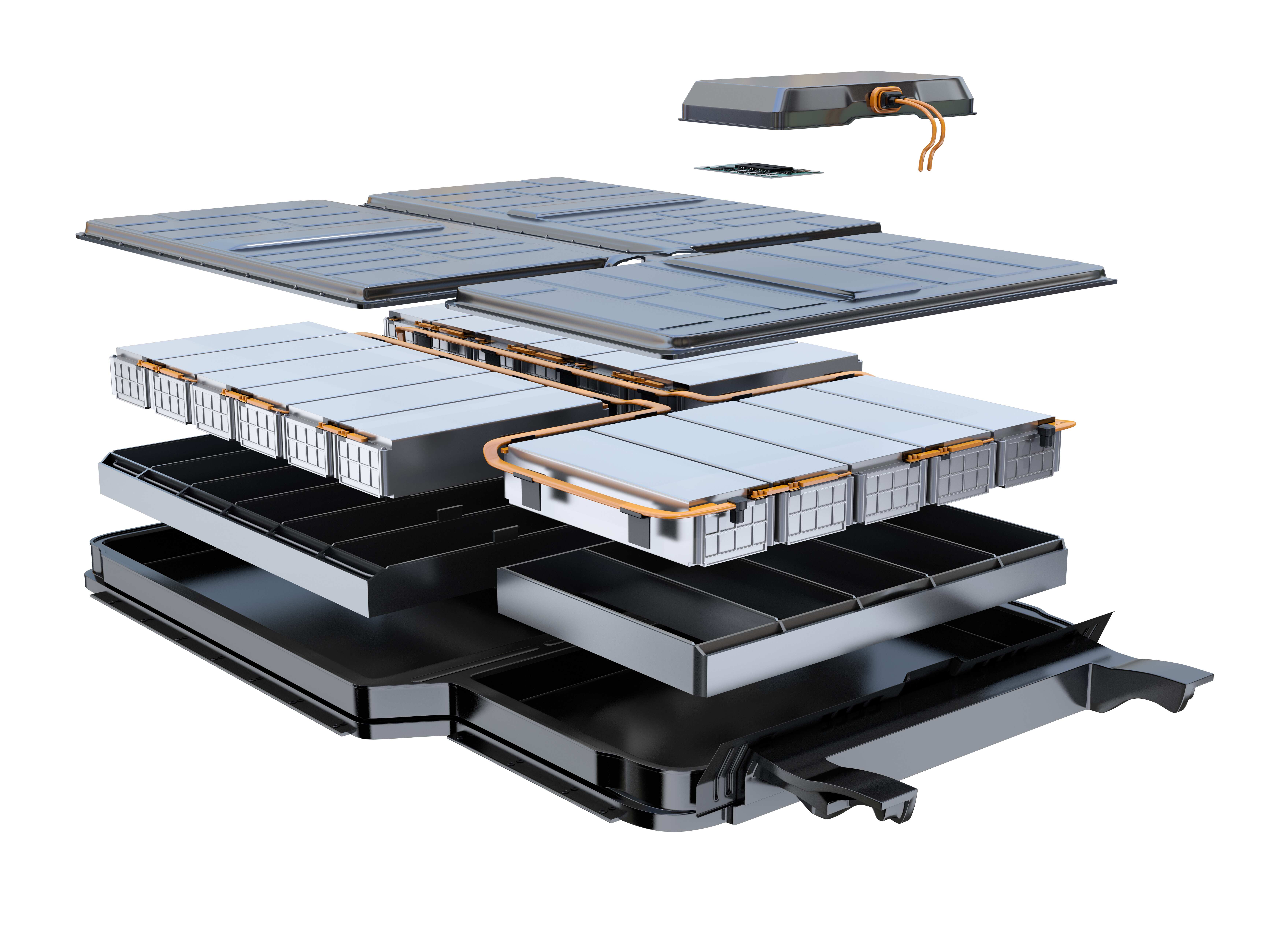

High-voltage battery

In designing a battery, the interplay between the design and simulation of stiffness, strength and crash behavior is of vital importance. From the cell module package through interface management to series development: we supply your solution from a single source. Especially important here are the topics of weight reduction and component quantities as well as the joining technologies (such as welding and bonding).

- Package

- Concept to series development

- Joining technology

Composites

In developing composite components, we work closely with Design, Simulation and, if required, the materials lab and in-house prototype production. This ensures a materials and load path-compliant design as well as a safe layout of fiber-reinforced thermosetting and thermoplastic components both in concept and series development. Only with this holistic approach can the full potential of functional integration be utilized.

- Integrated process chain from materials charts to prototype

- Concept development for various production methods