Your EMC testing laboratory in Munich – testing, measurement, simulation, and certification from a single source

Electromagnetic compatibility (EMC) is a fundamental prerequisite for the safe functioning, reliability, and approval of modern electronic systems. Due to advancing digitalization, electrification, and increasing networking, the requirements for EMC-compliant development, testing, and validation are constantly increasing.

Electronic assemblies, devices, and complete systems must be demonstrably immune to electromagnetic interference and at the same time comply with the applicable limits for electromagnetic emissions. This applies in particular to demanding and safety-relevant applications in the automotive industry, industrial electronics, medical technology, and other high-tech areas.

As an EMC testing laboratory in Munich, we support manufacturers, suppliers, and development departments with EMC testing, EMC simulation, and EMC certification of electronic systems. Our range of services covers the entire development process—from the early concept and design phase to development-accompanying tests to standard-compliant validation and certification according to international standards and OEM-specific requirements.

EMC testing, simulation, and development of electronic systems

The electromagnetic compatibility of electronic systems requires a structured approach throughout the entire development and testing process. From early simulation and targeted EMC testing to the validation of complete systems, we support our customers with comprehensive technical expertise and state-of-the-art testing infrastructure.

Our services cover all relevant areas of EMC—from specialized EMC testing laboratories to methodical development models and cross-industry applications to powerful test systems for sophisticated electric drives.

EMC Laboratory Munich

Infrastructure & Performance Data

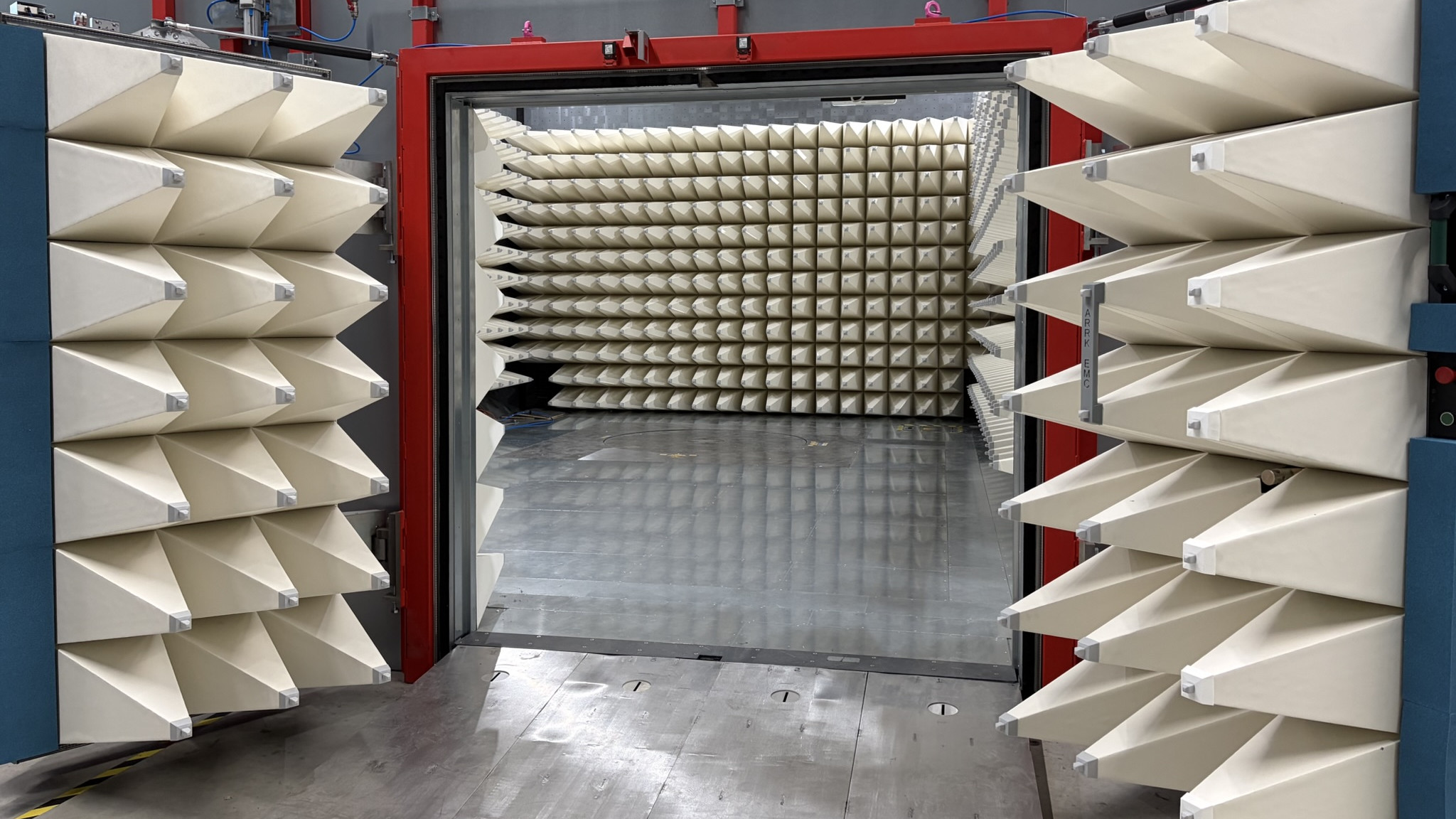

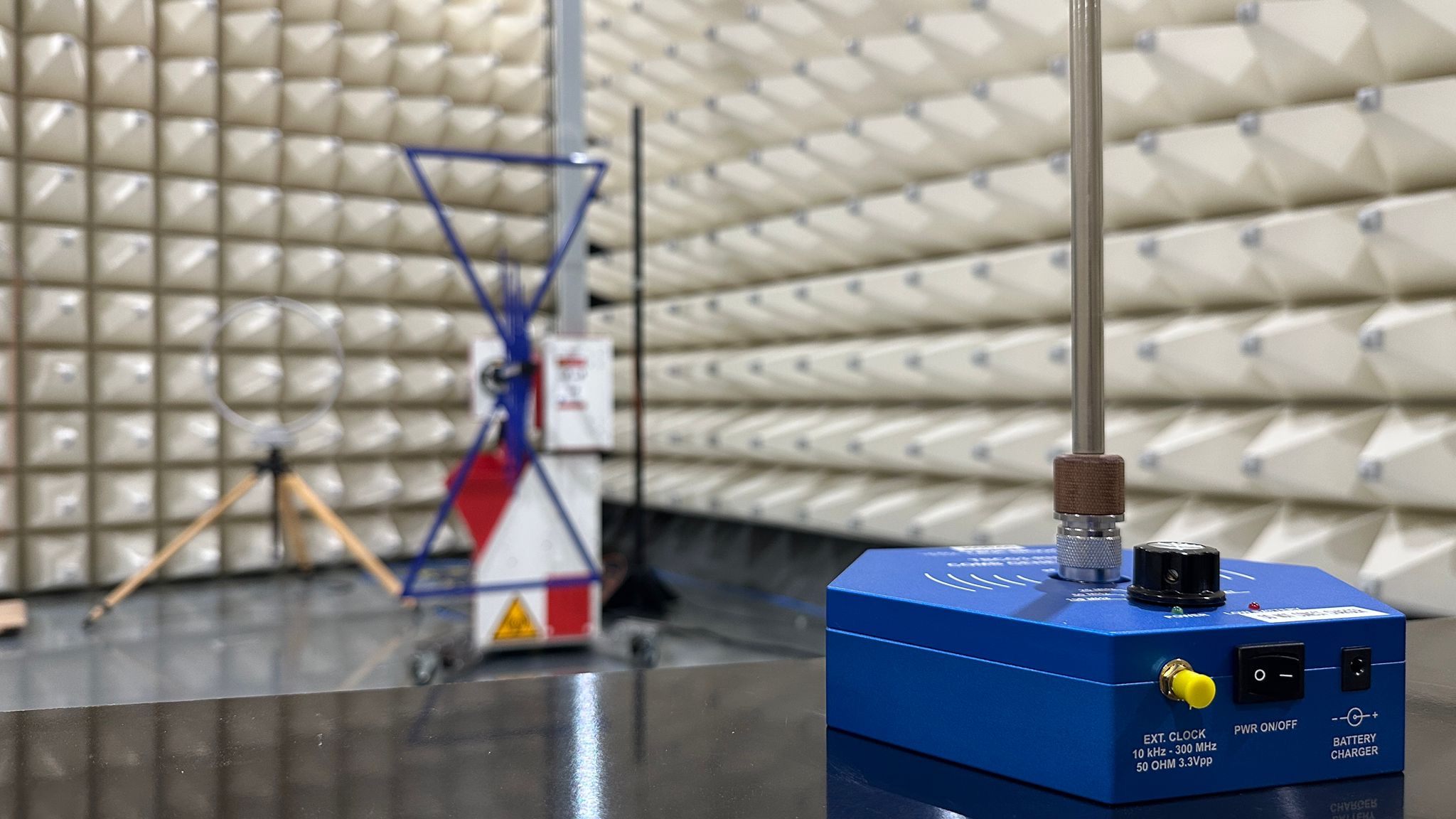

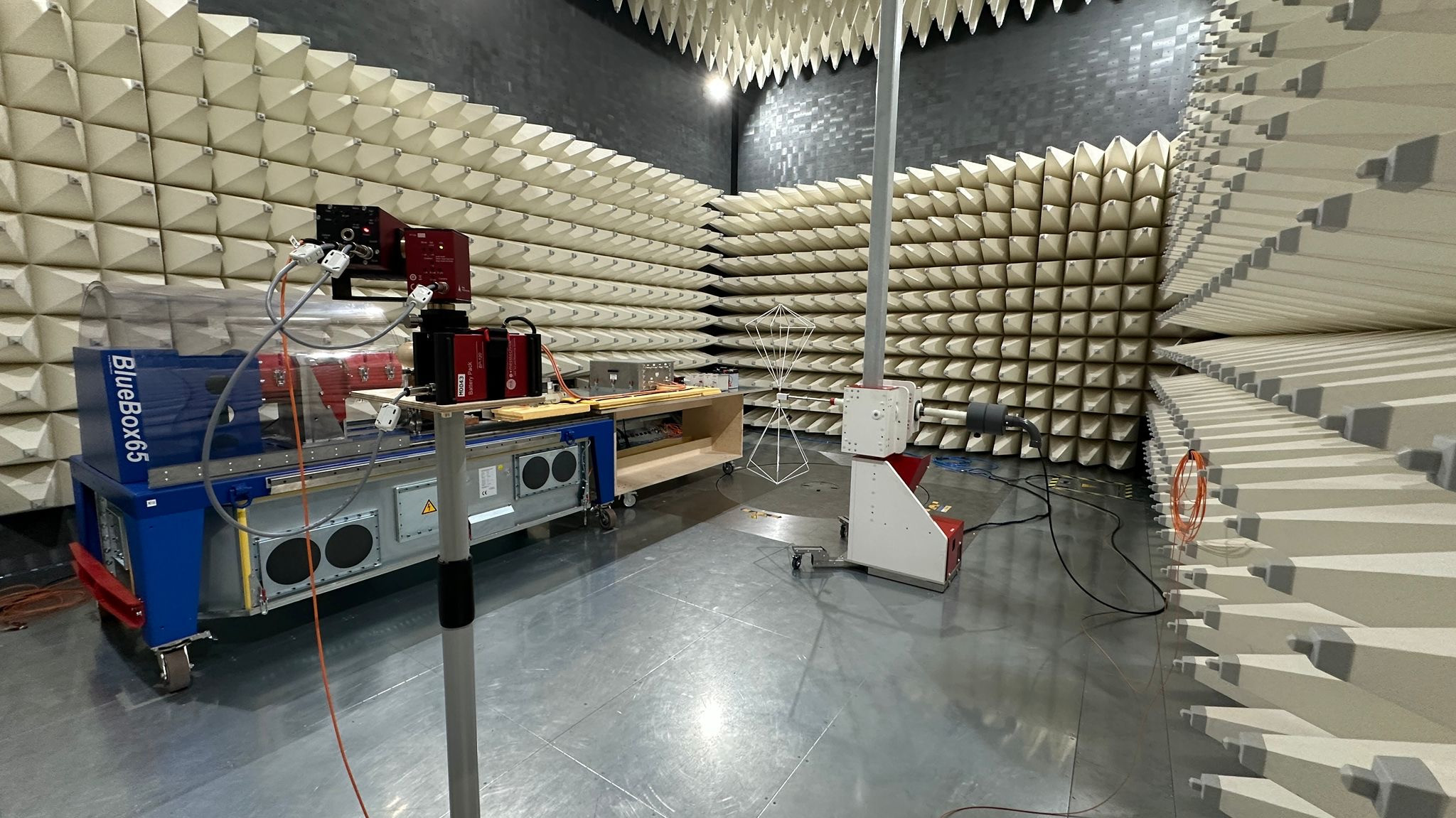

Our EMC testing laboratory is located in Munich and is centrally located within the city limits. This enables us to offer short distances, quick accessibility, and close, personal cooperation with development and project teams on site.

As an EMC testing laboratory, we offer a powerful and practical infrastructure for EMC testing of electronic assemblies, devices, and complete systems. The Munich laboratory is designed for EMC testing during development as well as for systematic preliminary testing, validation, and preparation for certification. All tests are carried out under controlled, reproducible, and realistic conditions.

Laboratory and chamber data

- Semi-anechoic EMC chamber for emission and immunity testing

- Absorber-lined chamber with non-combustible absorbers (building material class A1)

- Turntable with a load capacity of up to 2 tons and a diameter of 2 meters

- Hall floor load capacity up to 10 tons

- Chamber dimensions: 9.7 m × 6.5 m × 6.0 m

- Door dimensions: 2.1 m × 2.1 m

Air conditioning & environmental conditions

- Fully air-conditioned EMC chamber

- Temperature and humidity-controlled test area

- Typical control range: 18–28 °C, 40–60 % RH

- Reproducible and realistic test conditions

Cooling of test specimens

- Water cooling for water-cooled test objects

- Temperature range: –30 °C to +90 °C

- Control accuracy: ±0.1 °C

- Stable thermal boundary conditions during EMC tests

Electrical supply

- Flexible voltage and current supply for powerful test objects

- High voltage 60 VDC - 1000 V DC up to 250 A

- Low voltage up to 0 VDC – 60 VDC up to 250 A

- Three-phase AC supply up to 250 A

- Suitable for power electronics, inverters, and electric drive systems

Measuring and working areas

- Separate measuring and control room with direct connection to the chamber

- Real-time monitoring and evaluation of tests

- Working areas for short-term adjustments to the test specimen

- Direct repeat tests possible after modifications

EMC measurements, tests, and standards

In our EMC testing laboratory, we test the electromagnetic compatibility of electronic assemblies, devices, and complete systems under realistic and reproducible conditions. All tests are carried out in accordance with standards, tailored to specific projects, and in accordance with international standards and OEM-specific requirements. The tests and standards listed below represent a selection of typical procedures.

Interference emission

- Conducted interference emission (CISPR 11, CISPR 22, CISPR 25, CISPR 32)

- Emission measurements in the relevant frequency range according to CISPR

- Radiated interference emission (CISPR 11, CISPR 22, CISPR 25, CISPR 32)

Immunity

- ESD tests (IEC / EN 61000-4-2)

- Burst tests / EFT (IEC / EN 61000-4-4)

- Surge tests (IEC / EN 61000-4-5)

- Radiated RF immunity incl. ALSE (IEC / EN 61000-4-3, ISO 11452-2

- Conducted RF immunity (IEC / EN 61000-4-6, ISO 11452-4)

- BCI tests (ISO 11452-4)

- Magnetic field tests (IEC / EN 61000-4-8)

- Voltage dips and short interruptions (IEC / EN 61000-4-11)

OEM standards and project-specific tests

- EMC tests according to OEM-specific requirements

- Application of project-specific standards and test specifications

- Extended EMC tests according to customer and market requirements

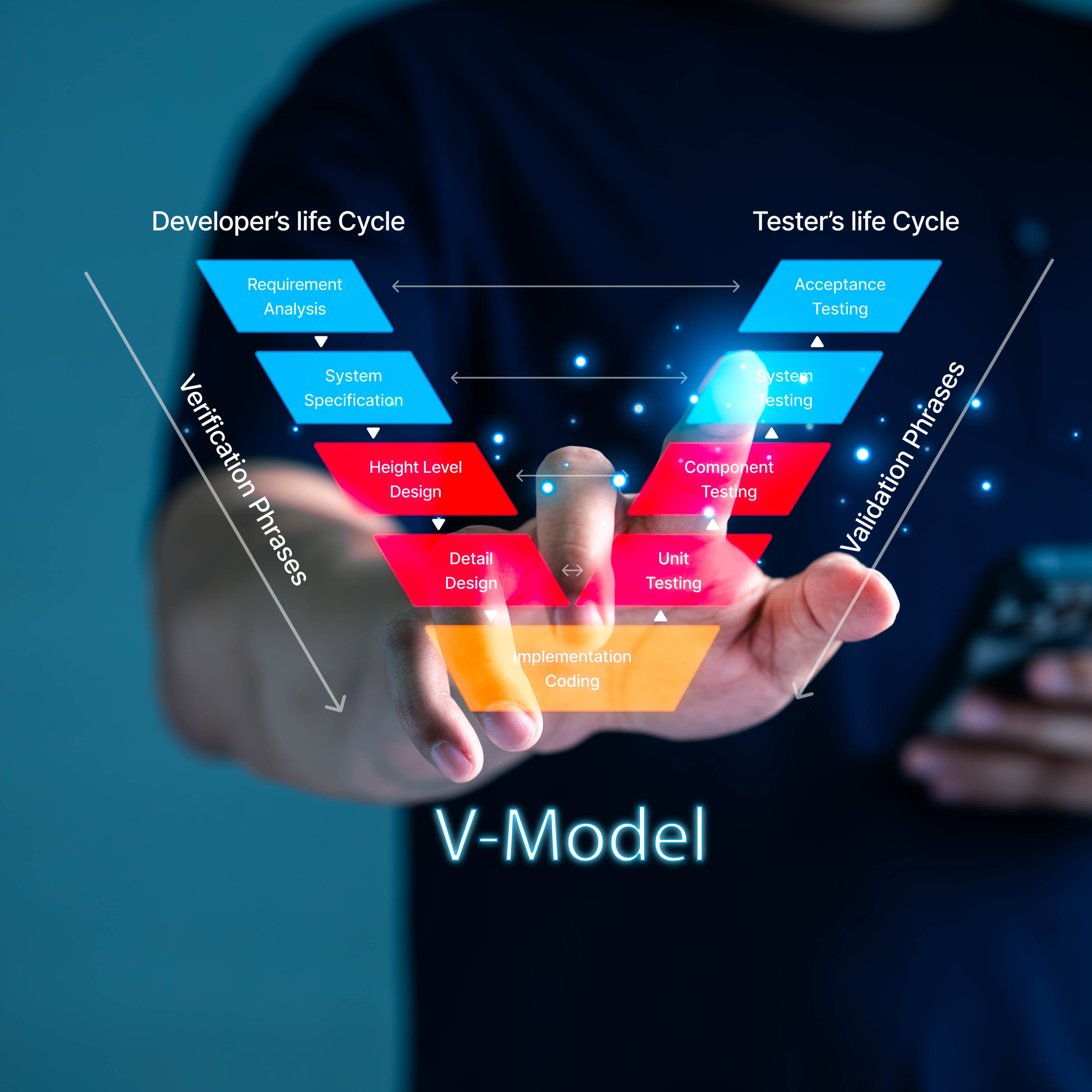

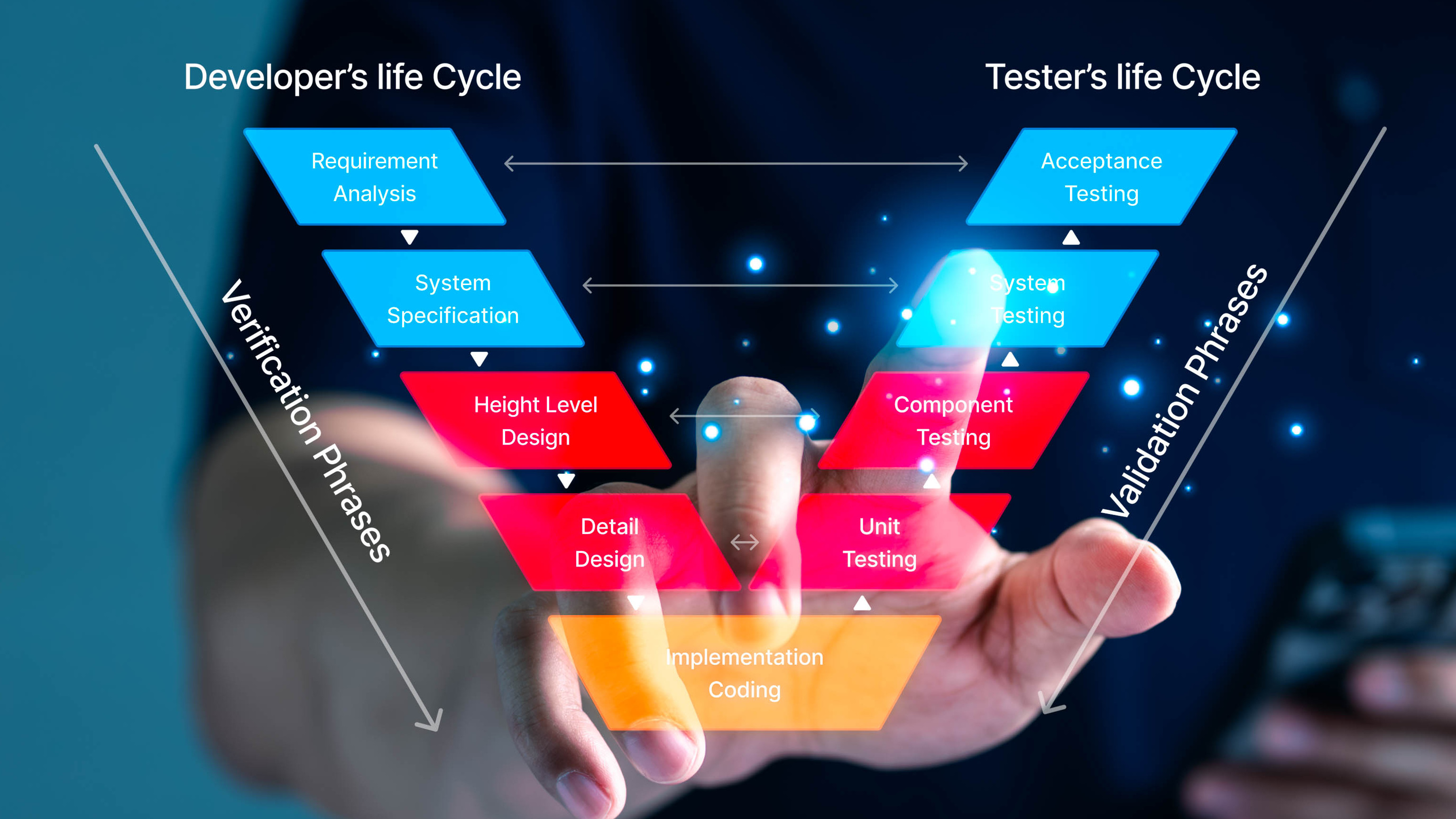

Holistic EMC and electronics development – from concept to certification

Our EMC expertise combines electronics development, EMC simulation, and EMC testing into a consistent, standards-compliant development process. Right from the early concept phase, we provide support in defining EMC requirements in accordance with international standards and OEM specifications and accompany the development process through to successful system validation and certification.

Through simulation-supported design, EMC-compliant circuit and layout design, and targeted measures for grounding, shielding, and filtering, we ensure that electromagnetic compatibility is not just tested, but developed from the outset.

Final verification and validation take place under realistic operating and environmental conditions in our EMC test laboratory – efficiently, reproducibly, and close to development.

Result: robust, interference-free, and certifiable electronic systems with shortened development cycles and high market readiness.

Requirement definition

- Definition of EMC requirements according to standards and OEM specifications

- Determination of limit values, test strategies, and development goals

System design & EMC simulation

- EMC-compliant system architecture

- Simulation of interference emission and immunity

- Grounding, shielding, and filter concepts

Detailed development of assemblies

- Circuit and printed circuit board development

- Optimization of critical signal and power areas

- EMC testing during development

System validation & certification

- Standard-compliant EMC validation

- Support with certification and OEM approvals

- Documentation and evaluation of results

System tests

- EMC testing of complete systems

- Reproducible tests under realistic operating conditions

HW/SW component testing

- EMC testing at the component level

- Early identification of critical EMC effects

Industries & Applications

Whether automotive, medical technology, industrial electronics, laboratory equipment, aerospace, defense, or consumer goods: We support EMC-relevant development and testing projects across all industries—from the early concept phase to series approval and sustainable quality assurance.

We see ourselves as a technical partner with a comprehensive understanding of EMC and many years of experience in demanding applications.

Other industries and customer-specific applications available on request.

Automotive

Laboratory and measurement technology

Medical Technology

Security and defense systems

Industrial Applications

Aerospace

Consumer Electronics

Household Appliances

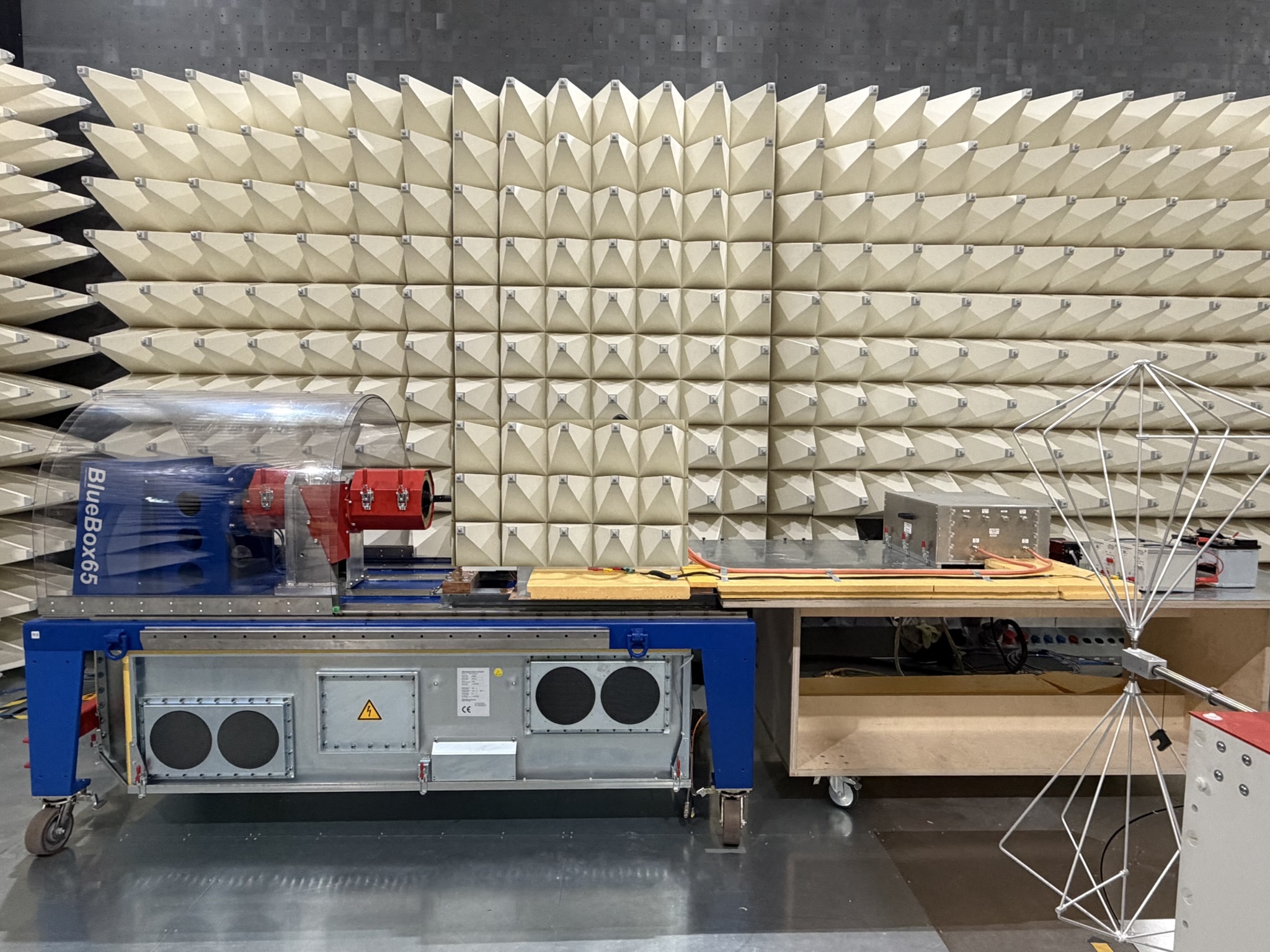

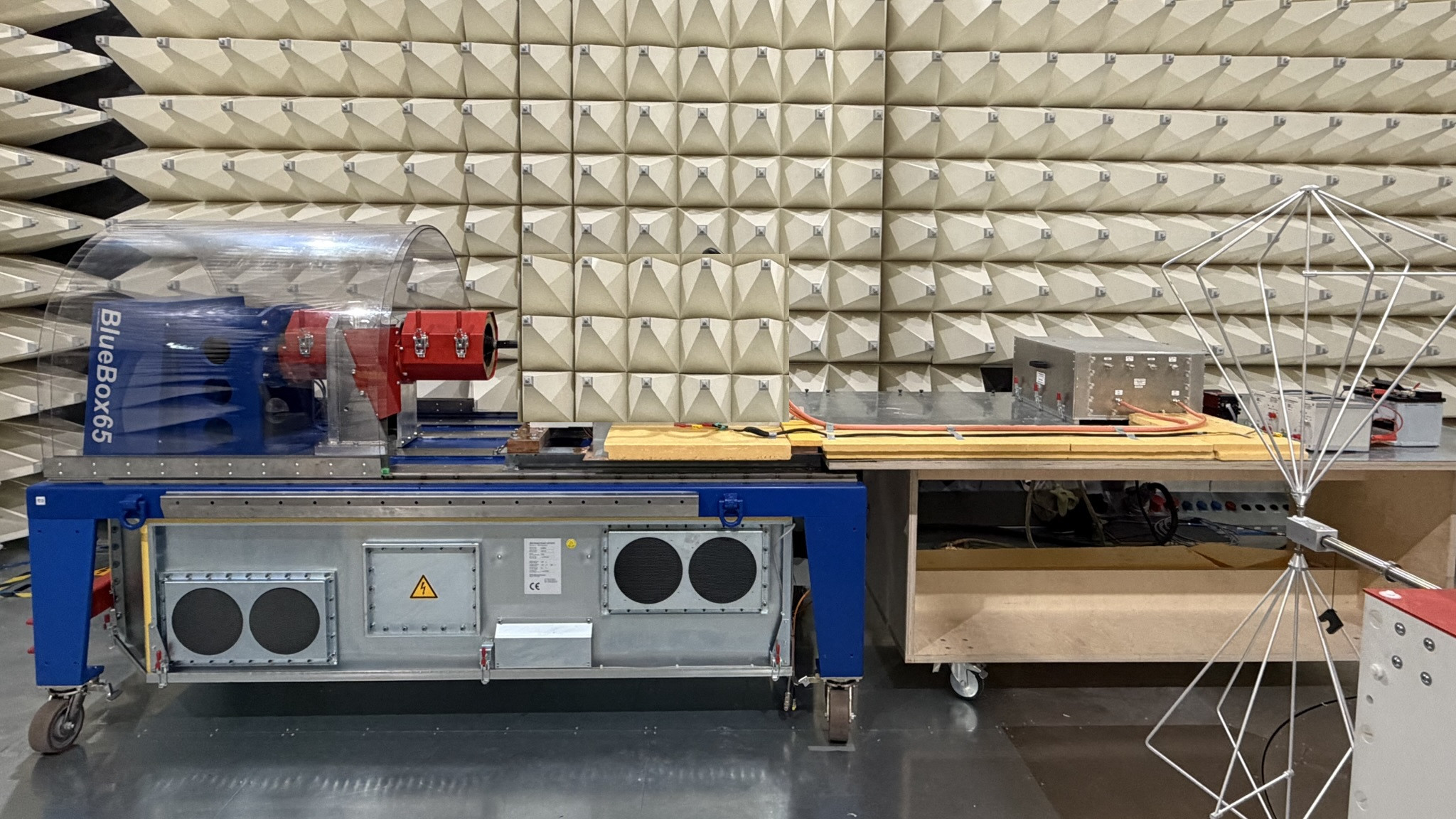

EMC test bench for electrical machines, drives, and electric motors

Electrical machines and drive systems generate demanding electromagnetic interactions due to high power outputs, fast switching operations, and complex control concepts. For safe operation, standard compliance, and series approval, a system-oriented EMC evaluation under realistic operating conditions is crucial.

Our EMC test bench enables the standard-compliant testing of electrical machines, inverters, and complete drive systems of various designs—from industrial drives to laboratory and special machines to electric motors with high power density. The tests are carried out directly in the EMC environment and reliably simulate real operating conditions.

By directly integrating the test bench into our EMC testing infrastructure, we enable reproducible, reliable, and standard-compliant EMC measurements on electrical machines and drive systems – from analysis during development to final validation.

EMC measurements on the test bench

- Radiated interference emission (EMI)

- Standard-compliant measurements in accordance with CISPR 25

- Radiated immunity (EMS)

- Tests in accordance with ISO 11452-2

- The solid test bench structure (BlueBox) can be regarded as a structurally similar reference for real installation situations

Further EMC tests, standards, and OEM/customer-specific requirements on request.

Technical performance data of the test bench

- Test power: up to 63 kW

- Maximum speed: up to 6,500 min⁻¹

- Maximum torque: up to 240 Nm

- Maximum test specimen weight: up to 1,000 kg

- Dimensions: approx. 2.5 × 1.4 × 1.3 m

EMC expertise centrally located in Munich - precisely tested, developed in accordance with standards, reliably secured! Contact our EMC testing laboratory in Munich for a non-binding initial technical consultation.

Your direct line to us emc@arrk-engineering.com